Reliable Membrane FiltrationEngineered Physical

Engineered Physical

Barrier System

Skid-mounted UF plants designed for SDI < 3.0. We engineer automated backwash logic and chemical cleaning protocols to ensure consistent flux.

- Guaranteed removal of colloidal silica

- Automated CEB (Chemically Enhanced Backwash)

- PVDF / PES Membrane Chemistries

- Plug-and-play skid integration

The Operator's Challenge

Inconsistent Feed, Unpredictable Output

Without a reliable barrier, raw water variability can wreak havoc on your process stability.

High Turbidity Spikes

Sudden increases in suspended solids from surface water sources can overwhelm traditional filters, leading to breakthrough and contamination.

Biological Risks

Standard clarification often fails to fully remove bacteria and pathogens, posing regulatory risks and safety hazards for product water.

Downstream Clogging

Colloidal foulants pass through media filters, rapidly clogging expensive Reverse Osmosis membranes and forcing frequent shutdowns.

Ultrafiltration:

Your Definitive Physical Barrier

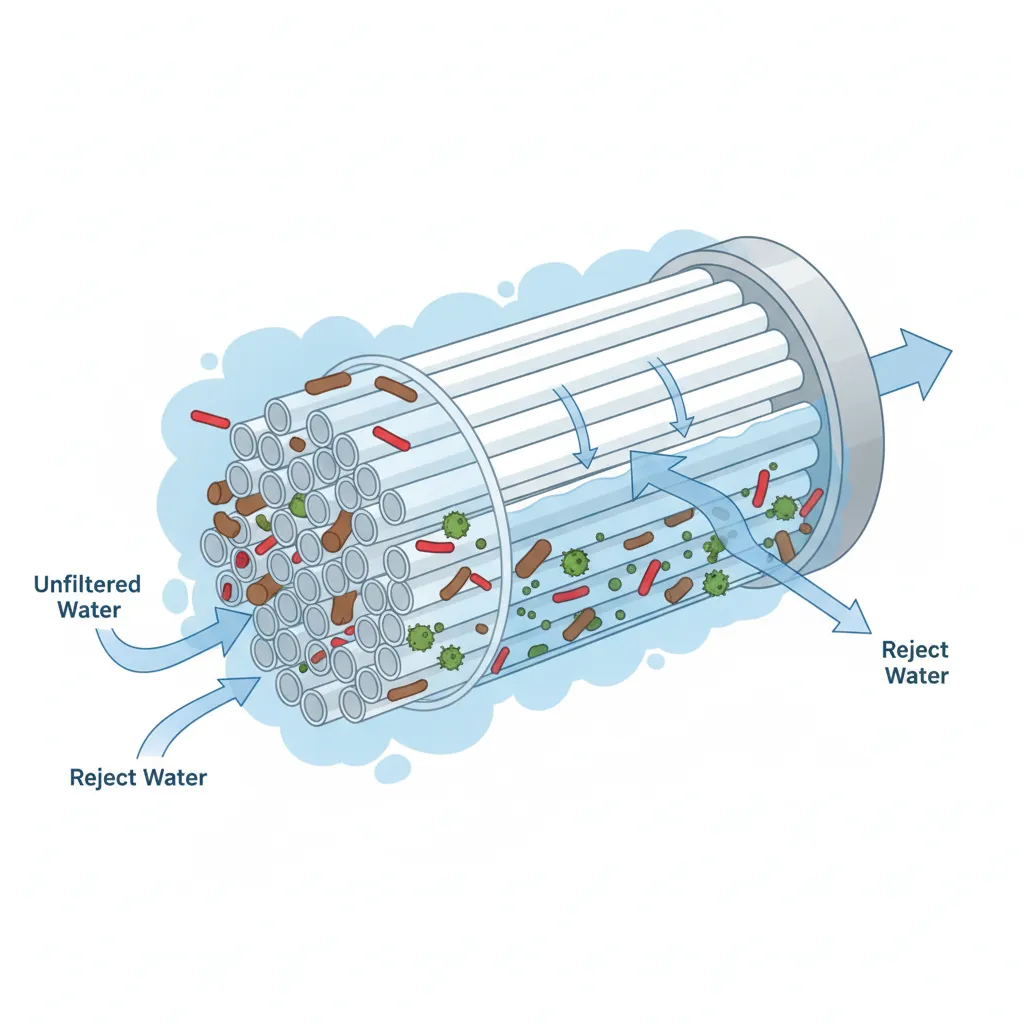

Ultrafiltration (UF) is not about chemical separation—it's about mechanical certainty. It introduces a membrane barrier with a pore size of approximately 0.02 microns.

Unlike sand filters that rely on depth filtration and can allow particle breakthrough during pressure surges, UF acts as an absolute sieve. No particle larger than the pore size can physically pass through.

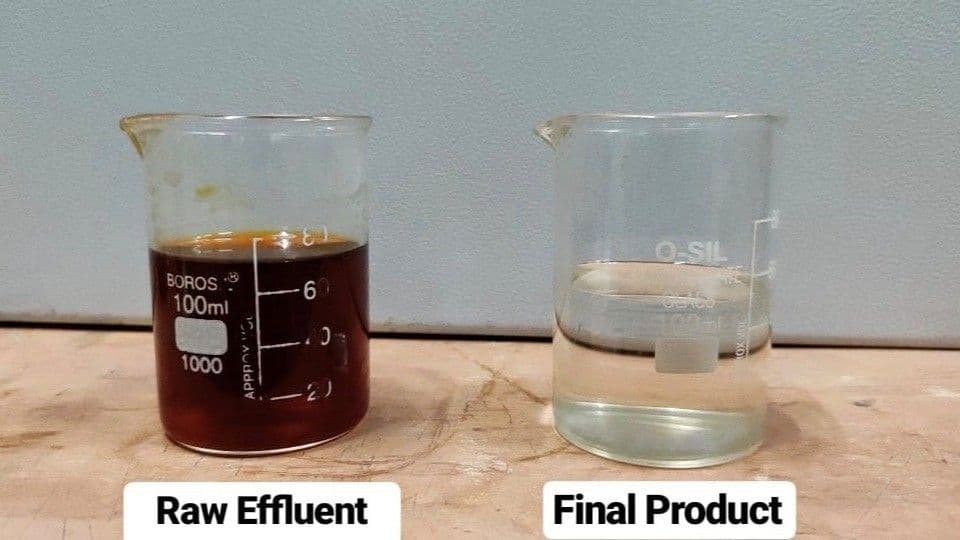

"It is the pretreatment workhorse that transforms variable surface water into a consistent, crystal-clear feed for RO or industrial use."

Absolute Seal

Physical exclusion of pathogens and solids.

Stable SDI

Consistently low Silt Density Index (< 3.0).

Long Life

Durable PVDF/PES membranes.

Auto-Backwash

Self-cleaning for continuous uptime.

Process Mechanics

How Ultrafiltration Works

UF operates on a simple size-exclusion principle. Feed water is pumped into hollow fiber modules or pressure vessels.

Micron-Scale Sieving

The membrane walls feature microscopic pores (0.01 – 0.1 µm). While water molecules and dissolved salts flow through freely, suspended solids and colloids are physically blocked.

Cross-Flow & Dead-End

Systems can operate in dead-end mode for higher recovery or cross-flow to minimize fouling, depending on feed water quality.

Backwashing Cycles

Accumulated solids are periodically flushed out via automated backwashing, restoring flux without manual intervention.

Key Operational Advantages

Why operators prefer UF for critical filtration steps.

Consistent Permeate

Delivers filtrate with Turbidity < 0.1 NTU regardless of feed quality.

RO Protection

Significantly reduces fouling of downstream RO elements, extending their life.

Pathogen Barrier

Log 4 reduction (99.99%) of viruses and bacteria for safe water.

Less Chemicals

Reduces or eliminates the need for coagulants and flocculants.

Compact Footprint

Small modular design compared to massive sand filtration tanks.

Automated Cleaning

Integrated Clean-In-Place (CIP) and backwash protocols.

System Characteristics

Filtration Spectrum

0.01 - 0.1 Microns

Operating Pressure

Low (1-4 Bar / 15-60 PSI)

Key Removals

SS, Colloids, Bacteria, Silt

Membrane Material

Modified PES / PVDF

Configuration

Hollow Fiber (Inside-Out / Outside-In)

Typical Applications

RO Pretreatment

Protecting RO membranes from fouling by removing silt and colloids.

Drinking Water

Municipal water treatment for pathogen removal without chemicals.

Wastewater Recycling

Tertiary treatment to make wastewater safe for reuse.

Process Water

Surface water clarification for industrial cooling and makeup.

Food & Beverage

Clarification of juices, removing haze while keeping flavor.

Desalination

Pre-conditioning seawater to prevent clogging in SWRO systems.

Frequently Asked Questions

Expert answers to common Ultrafiltration questions.

Why Choose Our UF Solutions?

We design Ultrafiltration systems that prioritize operational reliability. Our skid-mounted units are engineered for easy integration, rapid commissioning, and long-term stability in harsh industrial environments.

99.9%

Pathogen Removal

< 0.1

Filtrate NTU

Low

Energy Footprint

Auto

Backwash Cycles

Our Network

Trusted by Industry Leaders

Partnering with global organizations to deliver sustainable engineering excellence and innovative water treatment solutions.

Water Treatment Insights

Get in touch with our experts

Have a custom requirement? Book a free consultation with our engineering team or drop us a message.

Contact Information

Call Us

020-27475272/73

+91 82754 86263

Mon-Sat, 9:30 AM to 6:30 PM

Visit HQ

S. No. 1, 5, 11-13, B Wing,

Mahalaxmi Heights, Mumbai-Pune Rd,

Pimpri, Pune-18, MH, INDIA.