Advanced Closed Loop RO

Engineered for Longevity.

Hydraulically Balanced RO Design.

Stop RO failure before it starts. RO-Matrix combines Closed Loop efficiency with real-time smart monitoring to ensure predictable and reliable performance up to 98% recovery.

The Limits of Traditional RO

In legacy systems, sequential membrane stages are fed by a single steady-state pump. This forces lead arrays to operate at high flux while tail arrays suffer from low crossflow and concentration polarization, making them highly prone to fouling and sealing.

The Closed Loop Advantage

Closed Loop Reverse Osmosis improves on traditional design by concentrating feed water in time vs space.

Instead of multiple stages, it uses a single stage with 100% brine recirculation. A variable-speed pump increases frequency with each cycle to ensure membranes get exactly the flux they need—neither too much nor too little.

Traditional RO

- Uneven flux distribution

- High fouling in tail elements

- Max ~75% recovery typical

- Fixed pressure wastes energy

Closed Loop RO

- Even flux distribution

- Independent crossflow control

- Up to 98% water recovery

- Variable pressure saves power

Ionic Engineering solves this with the Matrix Real-Time Monitoring System

Unmatched Operational Resilience

By decoupling crossflow from recovery, Closed Loop RO adapts to changing conditions in real-time.

Biofouling Resistance

Salinity and pressure constantly cycle inside the system. This harsh, fluctuating environment deprives microorganisms of the stability they need to survive, naturally inhibiting growth.

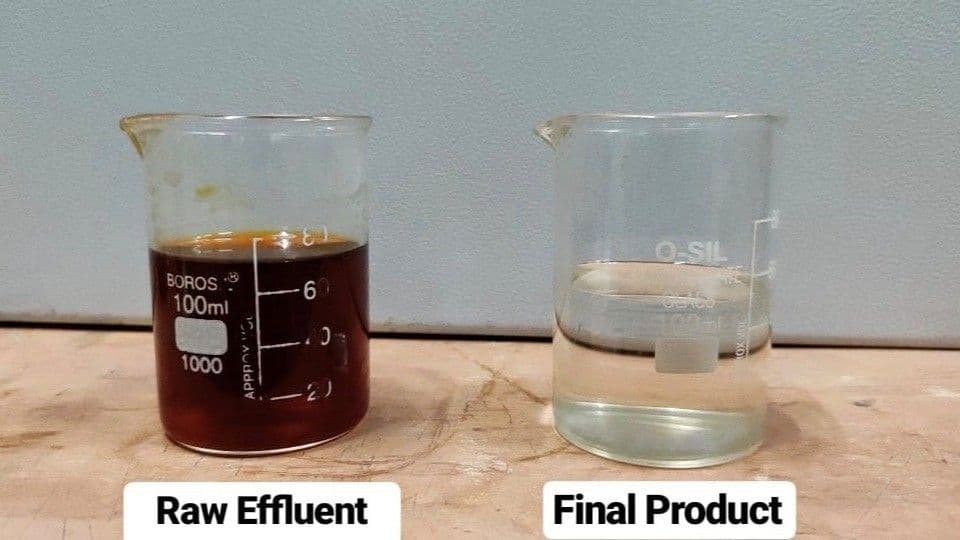

Scaling Prevention

We can push salts into supersaturation without scaling. The system flushes supersaturated waste before dissolved salts have time to crystallize, allowing extremely high recovery rates.

Total Flexibility

The system automatically adjusts excessive feed pressure, recovery, or flux based on user-defined set-points. It adapts to seasonal water quality changes without manual recalibration.

How the Process Work

1

Closed Loop Mode

100% of the brine is recirculated. The high-pressure pump feeds the loop while a circulation pump maintains optimal crossflow.

2

Concentration

The system concentrates feedwater over time (cycles) rather than space. Salinity increases gradually.

3

Plug Flow Sweep

Once the set recovery (e.g., 95%) is reached, the concentrated brine is flushed out in a single plug-flow sweep and replaced with fresh feed.

SYSTEM STATUS

RECOVERY: 96.5%

CROSSFLOW: OPTIMIZED

Industries & Applications

Ideal for sites with varying feedwater or high silica concentrations.

Industrial Process Water

Reliable high-purity water for manufacturing.

Food & Beverage

Ingredient water and consistent product quality.

Boiler Pretreatment

High silica removal to protect boiler efficiency.

Irrigation Desalination

Maximizing water usage for agriculture.

Refineries & Chemicals

Handling tough, variable waste streams.

Metals & Plastics

Zero Liquid Discharge (ZLD) minimization.

Frequently Asked Questions

Technical details about the Closed Loop System.

Technical Resources

Download detailed specifications and engineering data.

Closed Loop Desal Reverse Osmosis RO-Matrix

Our Network

Trusted by Industry Leaders

Partnering with global organizations to deliver sustainable engineering excellence and innovative water treatment solutions.

Latest Insights

Get in touch with our experts

Have a custom requirement? Book a free consultation with our engineering team or drop us a message.

Contact Information

Call Us

020-27475272/73

+91 82754 86263

Mon-Sat, 9:30 AM to 6:30 PM

Visit HQ

S. No. 1, 5, 11-13, B Wing,

Mahalaxmi Heights, Mumbai-Pune Rd,

Pimpri, Pune-18, MH, INDIA.